03.11.2022

Development and commercialization of 3D printing in medicine

In Poland, at this point, there are about 1,780 people waiting for an organ transplant. Of which at least a few dozen people - in an urgent procedure. Until recently, the only possible solution for improving the health of this group of the population was to obtain organs from a potential donor. However, more and more information about innovations in 3D organ printing is being reported in the mass media. At what stage of advancement is the 3D printing market in medicine, and will organ printing in the future be a non-problematic process? Or will organs created with this technique be seen on store shelves?

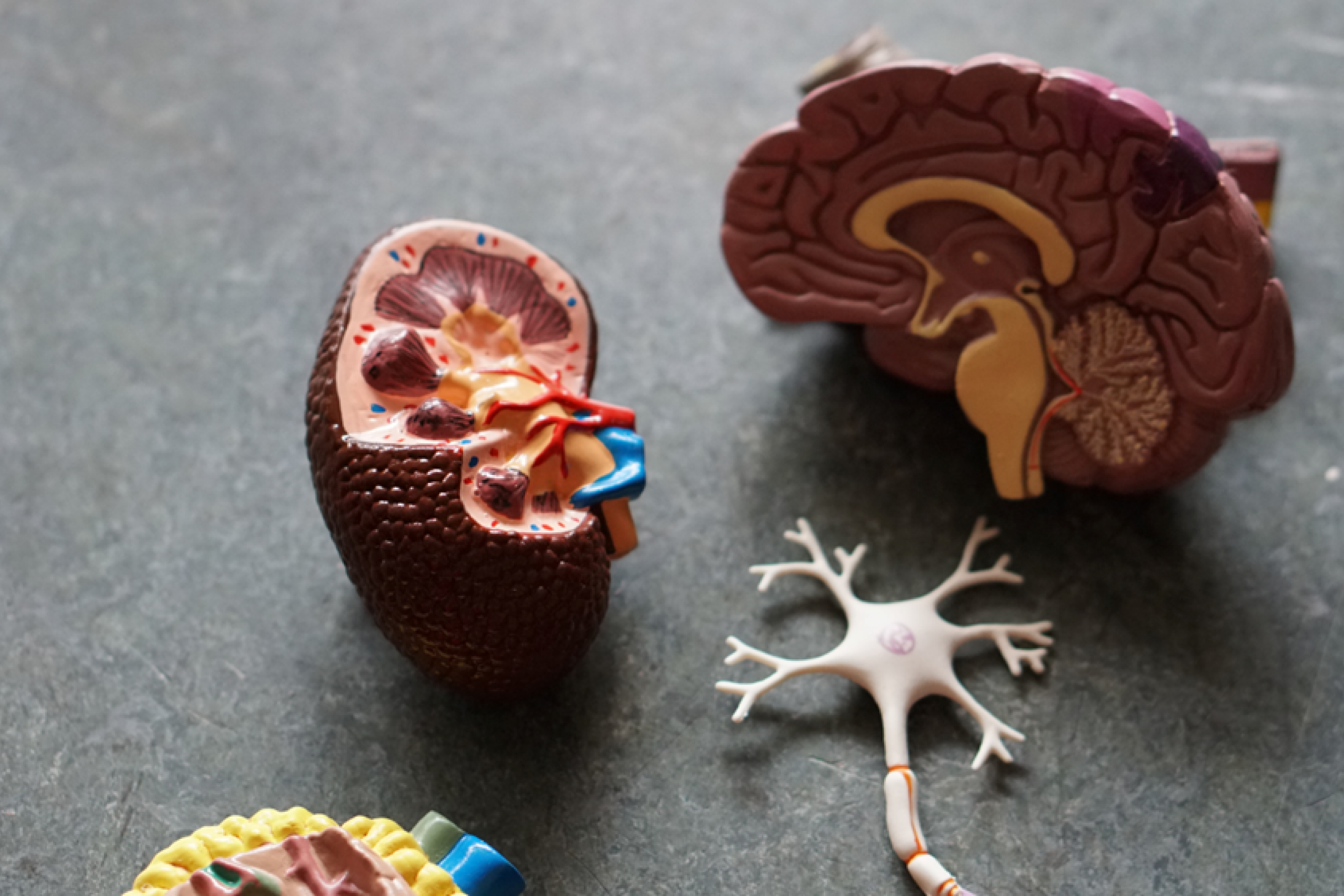

Tissue engineering - what is it really?

Tissue engineering is a field of science that deals with the application of medical knowledge and engineering

materials to produce replacements for damaged organs and tissues. The first efforts at

Repairing defects in the body were undertaken as early as the time of the ancient Egyptians, who believed in life

the afterlife and were extremely concerned with the integrity of the body. Archaeological research has proven that even then

dentures, for example, were used. However, the term tissue engineering itself was not coined until 1988

year during a meeting of the National Science Foundation. The 1990s saw a surge in

research to develop replacements for almost every organ, and numerous

innovations, which was a milestone for the medical 3D printing market.

Printing process

To begin the process of organ bioprinting, doctors usually start with a biopsy - the removal of part of an organ or

removing a small piece of tissue. This allows the cells to be separated and cultured outside the

human body. Cell development takes place inside a special sterile incubator or

bioreactor, which by their conditions resemble the internal temperature and oxygenation of the human body.

The cells are then left to mix with the biotouch, the non-cellular part of which can be made into a

lab. Biomaterials used in the printing process must be non-toxic, biodegradable and

biocompatible, in order to avoid a negative reaction from the body.

In the next step, doctors insert the biotouch into the printing chamber. The printers are programmed in this

way that they contain patient imaging data from X-rays and scans. Thanks to this

it is possible to create tissues with personalized properties. The length of the printing process depends on

on many factors, such as the type of organ or tissue being printed. However, it usually lasts from

several to several hours.

When organs are harvested from a donor, it is necessary to immediately place them in a bioreactor,

because otherwise the cells will die. In addition, it is necessary to perfuse the organ, which involves

providing it with fluid (usually blood or a blood substitute). In the case of organ printing, there are a number of issues

and the challenges that must be met to make the printed organ function like a real, human organ

In the body. Once the printed organ is implanted in the patient, it will degrade over time. Part of

People may think that then the tissue will disintegrate. Nothing could be further from the truth! The cells then sense that

The bridge gives way and they no longer have stable support. They then form their own glue and bridge - just like the

They do this in every human body.

What level of sophistication are we at when it comes to bioprinting?

Despite the fact that tissue engineering is a field that is growing at a rapid pace, by

Introduction of numerous innovative technologies, implantation of fully functioning printed

organs into the human body would be a true revolution in the world of medicine, for which, unfortunately, we must

wait probably at least a couple of years. However, once society has reached that stage,

Commercialization of bioprinting should not be a problem.

All over the world, the demand for organ transplants is enormous. This is causing a continuous increase in the number of

innovation, research and work on organ printing. Those who manage to live to see a transplant must, by

the rest of his life to take special immunosuppressive drugs to prevent organ rejection.

In the case of printing, the situation would be quite different. It would provide a sufficient number of

transplant tissues that would be printed from the patient's cells - so the risk of rejection will be

much smaller.

Poland's success in 3D printing

In March 2019, there was a lot of media coverage about the great success of Poles who managed to print the

The first fully functional pancreas prototype. The team, led by Michal Wszola, M.D., Ph.

Immediately after printing the organ, he began testing it on animals. The test results were very promising,

and the material from which the pancreas was made turned out to be completely non-toxic. The organ was functional, making it

The team is preparing to conduct further studies that will ultimately develop the developed

technology enough to make further research with the human body possible.

However, due to a number of difficulties and printing requirements, such as creating a

appropriate conditions resembling a human organism in a bioreactor, the topic of 3D printing still remains

future topic. Creating a fully functional organ, ready to be implanted

into the human body is problematic and requires a lot of research and testing.

Is printing organs at home in the future possible?

All biological prints must be printed on special 3D bioprinters. Despite the fact that such

printer you can create yourself (which, according to researchers at Carnegie Mellon University, is a

possible to build for as little as $500), it still has to meet a number of requirements and standards, as the

In order to print an organ, living cells are needed, and they must be maintained in appropriate

conditions, which is not easy to achieve.

Moreover, everything that is implanted in the human body must be manufactured on certified

devices that comply with medical standards. Therefore, even if we build the bioprinter ourselves

- It will not be certified and therefore bioprinting at home will not be possible. Produced

The material must be biocompatible - otherwise it may cause undesirable effects in the human

organism, in addition, legal regulations are also another obstacle.

Brain bio

Researchers from the University of Montreal, the Federal University of Santa Catarina and Concordia University

have announced that they have succeeded in printing live mouse brain cells using bioprinting technology.

The vast majority of neurons were still alive two days after printing.

Numerous studies have been conducted to determine the capacity of the cells, which can greatly help

In the development of this market.

However, despite numerous advances in this field, cell replacements and printing fully

of a functioning brain is still a question of the future. We need numerous studies, tests, time

and financial assistance so that bioprinting can be commercialized.

Success getting closer

Tissue engineering is a field that solves many medical problems. Despite numerous innovations

and research, however, we still have to wait for this market to develop, and for organ implantation to

produced with the help of a bioprinter has become the norm. The joint effort of doctors and scientists is increasingly

is showing promising results, and we can hear in the media about further successes in transplantation

using this technology. The development of this field is extremely important and could completely

revolutionize the world of medicine, thus saving many lives.